SENTO operates an ISO-certified investment casting factory with state-of-the-art machining facilities. We are able to supply raw castings, roughly machined and finished castings. We manufacture cast parts made of stainless steel in accordance with order specifications and castings are then supplied with all the necessary certification.

Sento Food grade high quality precision stainless steel casting

We are your professional manufacturer of 304/316 stainless steel casting

Investment casting, also known as precision casting, is a lost wax process, unlike other casting processes, investment casting produces final parts with excellent surface quality and dimensional accuracy

We produce stainless steel castings and stainless steel faucets in our own factories. With state-of-the-art facilities of machining, we are able to offer total solutions for precision casting in stainless steel and other complex shape products that are completely ready to be built in and used. In addition to producing precision castings, this includes machining and drilling for cast pieces, the welding of sub-components and the performance of heat treatments,Acid Pickling , surface treatments ,laser engraving, cleaning,assembly and testing. All the activities are performed in our own factories.

Applications

Food machinery

Medical

Marine

Automotive

Industry

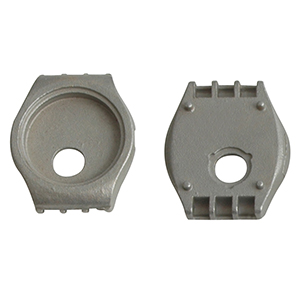

other cast parts

Faucet Parts

Watch Case

Tool

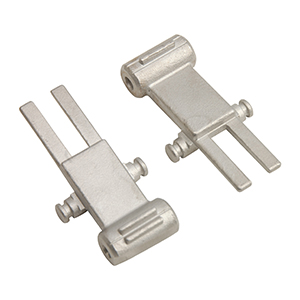

Handles&Hinges

Our flow Chart

Injection wax model & mold construction

Inspection and cleaning and repair are applied in these process

Mold build-up with layer coatings

The layer is created by immersing the pattern-tree in a mud bath and then sprinkling it with ceramic sand. It takes 7-9 times in a row and each layer is air dried for 15 hours in a drying room before the next round.

Pattern Meltout

Dewax with high temperature to get hollow shell

Pouring

Put stainless steel oil into mold, before that have to pre-heating the sand mold, so that they could bear high temperature of stainless steel oil

Burning

Keep burning to keep the oil to flow to every corner of the mold

Castings

Post treatment

Removing sands,sawing off or separating the cast parts from the steel pattern.

Grinding and visual inspection

The cut that remains after sawing is ground from the cast. A grinding tool is often used to properly grind the product.

As part of quality assurance, all products are visually inspected for possible casting defects. This check takes place against quality standards to ensure that all possible surface defects are properly corrected.

Heat treatments and acid pickling

Machining and surface treatment

welding, drilling, screwing and polishing

Inspection

After inspection, some valve components need to be polished and then moved to a new production line